Good info and links there.....I had read the beginnings of that tb1999 thread along time ago but forgot about it and now its an epic thread!

Looks like an accusump could be cheap insurance.

And I'm a huge Cosworth whore...but I'm wondering if they aren't just selling some stock application oil pump like they do with some of their other parts....

Eric Burmeister runs a very well built turbocharged Mazda 3 rally car.

He's running the 2.3.

He seems to know his stuff on Duratec/MZR's.

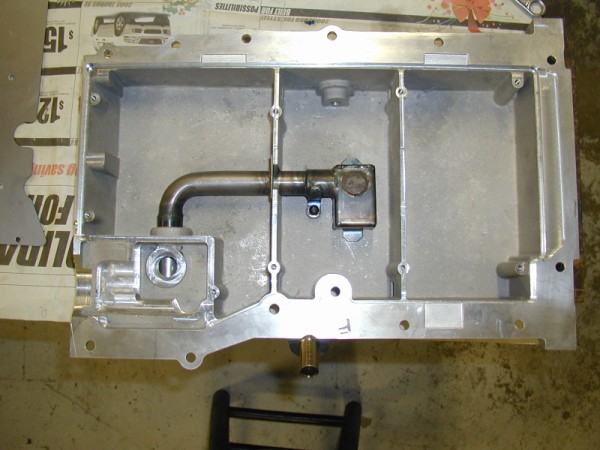

He ended up running the Cosworth/Titan UK dry sump that he's talking about in the following quote.

IIRC not just to prevent oiling isssues but that and so he could lower the engine without clearance issues.

But he talks about oil pumps too.

From a rallyanarchy thread:

"The Mazda6 has the biggest oil pump. Better than the Ranger/Mazda truck, Tribute/Escape, Mazda3, Focus, etc. They all have different pumps. Get the Mazda6 and change the spring.

Titan UK makes a nice low profile cast aluminum oil pan that allows a much lower engine mounting, but its too expensive and is made for use with the 2.0 oil pump (takes a lot of machining and custom pickup to work with the good pump)."