Suspension is simple, right?

It's there to confuse you and not work like you think it should. Things like, why when I lower my car can I feel bumps more? and why does my back now have shooting pain?

Well, it may be in part to your not choosing parts correctly or fully understanding what you just got yourself into. So lets cover the basics so you do understand.

Starting with the fundamentals.

Modern automotive suspension is at it's most basic, a lever. We all know how a lever works, but we don't quite understand it fully or the types of levers. A wrench is a lever, and we all know that too long of a wrench and we either strip bolts or snap them off. So we have some understanding that a long lever delivers more Torque vs a short one. The question is, do we really understand why?

Back to Elementary School.

We've all played on the teeter-totter and we know that the fat kid would always get us stuck at the top ... if you were the fat kid, I hate you. No matter what we did, we could not get down or our weight to move him up.

This is because we were both the same distance from the Fulcrum. So his weight being more than ours, the Center of Mass is in his favor, and he pushes us up.

But what if we moved his weight closer to the Fulcrum? Would we stand a chance at moving him up and down?

Yes we would!

This is because the lever on his end is now shorter while yours is the same length. This moves the Center of Mass closer to the Fulcrum putting less Mechanical Advantage on the fat kid.

![Image]()

So if he weighed 130# and I was 65#, I would need twice the distance from the Fulcrum than he to balance the teeter-totter. Pretty simple concept to understand. The longer the bar, the more weight you can move or more work you can do.

But suspension is not a teeter-totter, there are not 2 bars extending from the Fulcrum. There is only 1. Is that still a lever?

Yes it is. It is a second order lever, like a wheelbarrow. You are still dealing with moving mass about a Fulcrum, except this time the ability to balance the bar depends on input work and the Center of Mass.

Lets say we have something heavy in our wheelbarrow, 100# of dirt. How much effort (work) do we have to do to lift that dirt?

Well that is going to depend on where the Center of Mass is and how long the handles are. So we need to define those things. We'll say the Center of Mass is 12 inches from the Fulcrum and our handles are 48 inches long

Now the question we want an answer to is, how much weight will it feel like we're lifting?

This is found by, dividing the location of the Center of Mass by the length of the bar, times the weight.

So, (12/48)*100# = 25#

And you can also see that if the weight moves further from the Fulcrum it feels heavier, and closer it feels lighter.

Suspension follows this same concept. The longer the lever (control arm) the greater the Mechanical Advantage it has over the same weight; and with a fixed length lever, the closer to the Fulcrum the weight is, the greater the Mechanical Advantage the lever has.

So lets apply some of this to the Focus, starting with the rear suspension.

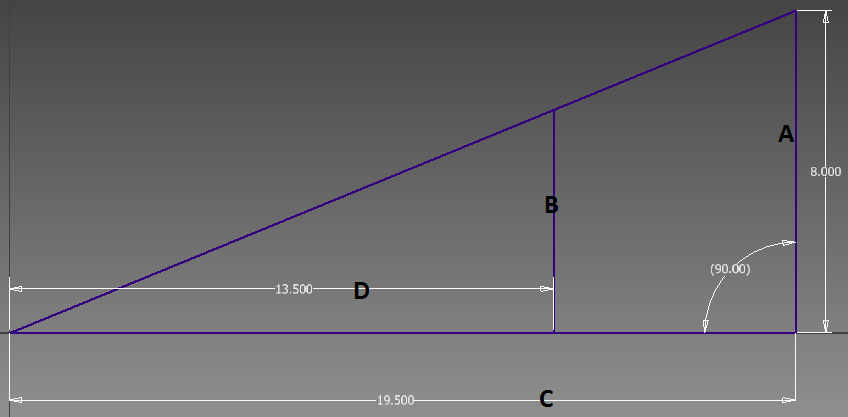

Our rear control arm is about 19.5 inches long.

The spring, which supports the weight, is about 13.5 inches from the Fulcrum.

If the car has a 65/35 weight distribution and total weight is 2,850#, that means a single rear corner weighs about (2,850#*0.35)/2 = 498.75#.

But what does it feel like to the spring?

Applying our formula, (13.5/19.5)*498.75# = 345.29#

So because of the Mechanical Advantage that levers have, we do not need a spring rated for the full weight of the corner to support it in a neutral state. The spring does not see the full weight because 30% of the weight is closer to the Fulcrum than the end of the lever (Control Arm), where it would see the full weight of the corner.

So what does this mean in the real world? Well you want your control arm to have a range of controllable motion in two directions, up and down. This has to be about a central point (Static Ride Height), which is where the Mechanical Advantage of the Control Arm is 1, equal to that of the spring.

When the rating of the spring becomes greater than the corner weight, there is no downward advantage of the Control Arm. What I mean by this is that for the spring to compress it takes more weight than is present on the corner. This means a rough/stiff ride. Any bump will have to be combined with vehicle weight to move the suspension. Which means small bumps will disrupt the occupants and the car will not remain 'flat' (parallel to the road surface).

In a typical and predominately road going car, you want a spring with a lower rating than the corner weight. This will allow both upward and downward movement of the control arm and provide a mildly smooth and undisruptive ride.

In a predominately racing situation involving corners, where occupant comfort is not important, a stiffer spring can be used. Cornering load or G Force will increase the effective corner weight and the spring will move in a upward direction.

Based on our assumed corner weights, a spring no heavier than the total rear weight times the Mechanical Advantage of the Control arm should be used, anything more is just excess that will never be used.

So this is a maximum spring rate of, (2,850#*0.35)*(13.5/16.5) = 816.14#

But this only applies to side to side movement. Once you add weight from acceleration or remove from braking, that maximum changes. But if you have a heavy spring up front and not much upward movement, the weight transfer is very little. So that 816# becomes a pretty fair number.

Simply put, when you see someone with a rear spring rate of higher than 800#/inch, the rear will not 'rotate' or compress unless you hit a very large bump. And than it will be very disruptive. The wheel will move up and down though.

So how do we know how heavy of spring to choose?

To answer this we need to know the Range of Motion of the Shock Absorber.

The factory 2000-2007 shock has a Range of Motion of about 8 inches. And if we want equal movement in upward and downward directions we want the shock centered in that range, 4 inches. This will mean that when cornering we will not ever lift a tire off the ground and reduce cornering stability.

So now we need to bring some Geometry into the mix. Since the Control Arm is a fixed length and we assume the tire stays 90 degrees to it, we can use right triangles to find a equilibrium for the Shock Absorber.

Now being we've already figured the corner weight it becomes easy to find how far the spring compresses and in turn how far the wheel moves.

This is simply, corner weight divided by spring rating times the distance of the spring from the Fulcrum.

So a stock Focus Rear Spring has a rating of about 117#/inch.

(2,850#*0.35)/2 = 498.75#

-(498.75# / 117#/inch) * (13.5/19.5) = -2.95 inches

This means that in stock form, under hard cornering the opposite tire to the direction of the corner can lift off the ground about an inch under full compression. Not a good situation.

But lets find out how hard we have to corner for this to happen. Enter triangles.

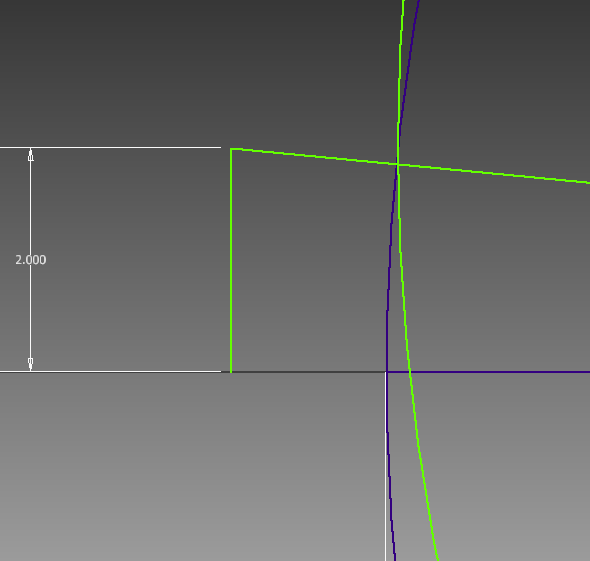

So at full tilt our tire has to compress 5 inches. But this doesn't mean the spring has to compress 5 inches. It is inboard of the wheel and only sees a fraction of the total movement. The nice thing about right triangles is that it's easy to find out how much.

![Image]()

If we know the length of A, C and D we can find the length of B.

B = D/C*A

So, 13.5/19.5*5 = 3.46 inches

Now multiply the spring movement by the spring rating,

3.46 inches * 117#/inch = 405#

Or if you want to speak in terms of G Force, 405#/498.8# = 0.81 G's

To keep all 4 wheel on the ground one of two things needs to happen. Either we much use a softer spring or a harder spring. The first option will mean the static ride height is centered in the Range of Motion of the Shock Absorber. The second option will reduce the compression of the spring, but the same relationship will remain to lifting a tire. Only now it will take more cornering load to do so.

Lets find out the optimal spring rate to keep all four on the ground.

This means our static height needs to compress the spring 4 inches, as we said above.

(498.8#/4 inches)*(13.5/19.5) = 86.33#/inch

But this means at full tilt the spring is maxed out at,

4 inches * 86.33#/inch = 345.3# or in terms of G Force, 345.3# / 498.8# = 0.69 G's

Pretty low by anyone's standards. Very comfortable ride, just not a feeling of stability. On hard corners you'd be on the bump stop fully and and deformity in the road surface would toss the car around. This is why the harder spring is the normal practice and you're left with lifting a tire.

Now how stiff of a spring is needed to not lift a tire? Well there is no good answer. You will always lift a tire and it's because no matter what spring what you choose, it will not be in the Center of Motion of the Shock Absorber. To do so requires moving the spring down, an adjustable spring perch.

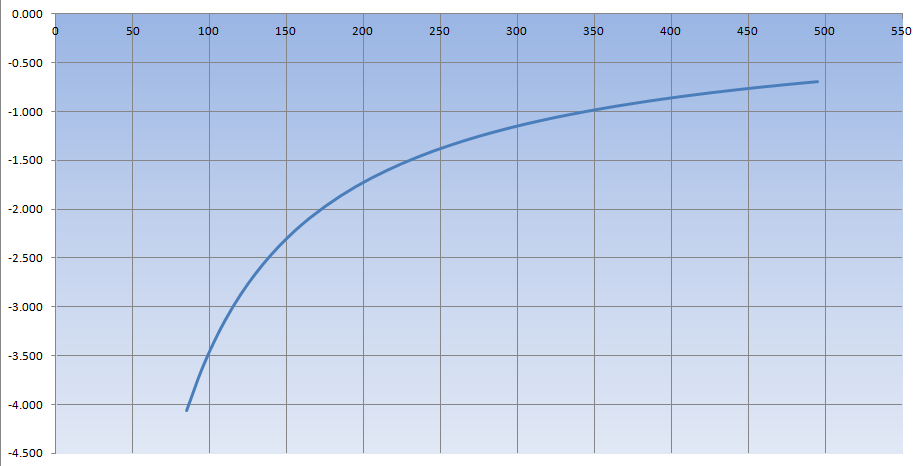

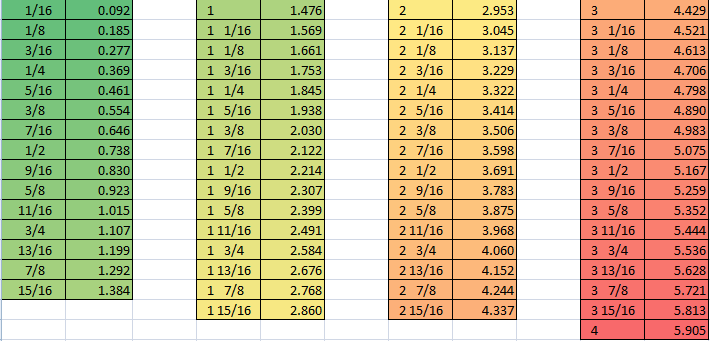

Here is the spring stiffness curve:

![Image]()

You can see that the relationship is not linear. There are actually what I would call comfort ranges:

85#/inch - 115#/inch - Ride Comfort Range

116#/inch - 165#/inch - Street Performance Range

166#/inch - 345#/inch - Street/Track Range

346#/inch + - Track Use Only.

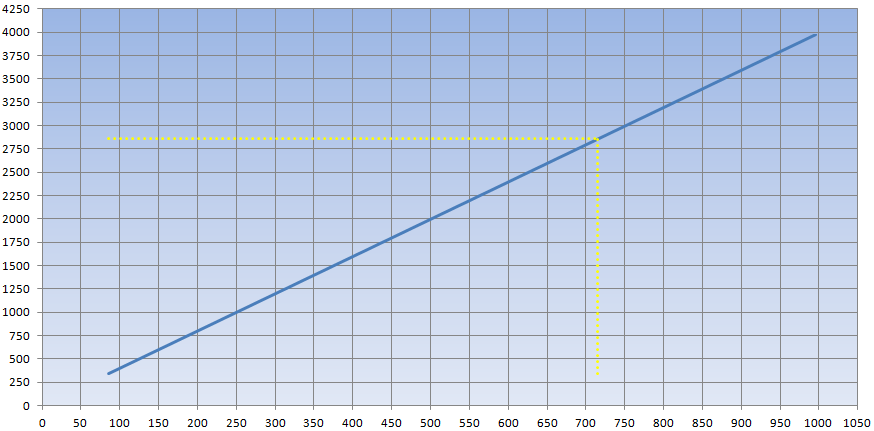

Sticking with the full range of motion of stock parts, this chart is the heaviest spring you would ever need (represented by the intersect of the yellow lines); remember this is for 4 inches of compression:

![Image]()

That yellow line represents full vehicle weight on one rear tire. There is basically no way you will ever see this. So in factory form, there is no reason you'll ever need a spring that heavy.

So what does that mean? I know I've seen guys who race talk about really high spring rates.

It means that suspension travel is reduced with them. And this is the case with any heavier than stock spring, Total travel will be less & range of motion reduced. So when someone talks about having a spring with a rating like 480#/inch, you know that they don't have as much travel as a stock Focus. That also means large bumps are going to upset the occupants more than stock, the car will roll more.

____________________________________________________________________

Instead of moving on to the front, I'm going to cover rear alignment. I didn't plan on this getting this long winded, so organization can't be that great (you should see the mess inside my head).

Rear Alignment

Now if you take nothing else away from this post, I beg you to remember this section. Burn it into your brain. Tell it to someone else. Anything that will ingrain it into your permanent memory. Which shouldn't be too difficult being it will fly in the face of everything you've been told previously.

When people ask for alignment recommendations or give them, there is always information missing. Information that is very important, Range of Motion. If you don't know the RoM you can not give a justifiable recommendation. This is because the static alignment really means nothing. You suspension moves through a RoM and as it does, alignment changes. Thankfully this is predictable. The goal is to keep all the wheels flat to the ground so the tire has the maximum contact patch and the maximum grip. So as one side gains Camber the other should loose Camber, keeping the tires parallel to the ground.

![Image]()

As the Control Arm moves through it's RoM it follows an arced path, just the same as using a string tied around a pencil to draw a circle. A fixed length rotating around a center point, makes a circle.

That being the case, the tire is only flat to the ground when the control arms are parallel. To find this point you need to line all the bolts heads up. With all of them parallel, you can set Camber to zero, and only zero.

Now when the car turns, as one side drops and inch, the other raises and inch, positive Camber will equal negative Camber.

It does not matter what ride height you have or what suspension. The only thing that matters is where the zero point of Camber is and that it's predictable.

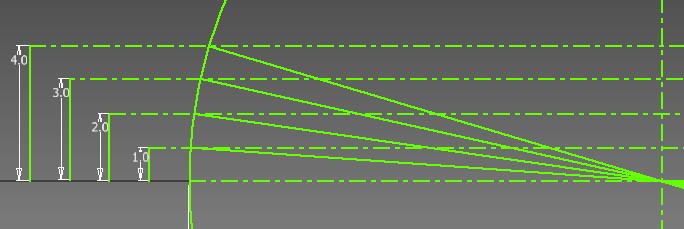

If done my way this will be your Camber Curve:

![Image]()

Now lets say you're lowered and the control arms aren't parallel, the wheel is located up from the Camber Adjustment Bolts and this is where you set Camber to zero.

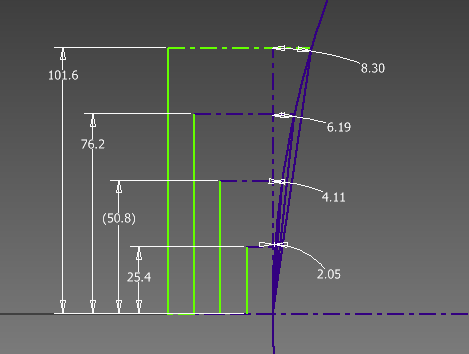

Blue line is the path the Control Arm follows, it is absolute. The green line is what the tire now follows.

![Image]()

So now instead of the tire being negative Camber until after the Control Arm passes parallel, it is going possessive. You may think it'll change at the same rate, but it doesn't. Instead of being 4.11°; you are actually at 6.36°.

It takes less suspension movement to change Camber, or Camber changes faster.

On the compression side, you'd expect 4.11° negative camber; you actually get 5.39° of negative. Which is not equal to the 6.36° of the extension side. This is removing contact patch from the road surface and can cause the rear to act 'odd'.

It is this rate of change that must be equal to keep all four on the ground equally to ensure predictable steering at all times.

So if you are lowered, check you camber by measuring how far the outboard Control Arm Bolt is above the centerline and look at the picture. If you're 1 inch above, you should have -2.05° static Camber.

*Going back over my drawings, it seems the control arm lengths weren't correct (19.5 inches long) so the drawings are not accurate.

The chart below is based on the 19.5 inch Control Arm:

![Image]()

It should also be noted that the distance measurement is movement of the outboard Control Arm Bolt (centerline) relative to all the bolts being parallel. If you measure based on wheel movement, they will not work. Moving the wheel 1 inch is not moving the bolt 1 inch, go back to the triangle section if this doesn't make sense.

Rule: Always set rear alignment when the four control arm bolts are parallel.

We also want an equation based on Control Arm length. My 19.5 inch length probably isn't exact and I don't know if the newer Foci have longer or shorter. But we want a way to adapt to anything.

To find the Camber angle you only need to know 2 things, Control Arm length and the distance from the arms being parallel. Then you can input those into my equation and it'll spit out the angle.

TAN-1 ((SQRT (Control Arm Length^2 + Distance from parallel^2) - Control Arm length) / Distance from parallel))

(the equation doesn't format correctly because I can't get superscript to work

If you are using Windows Calculator, you want to be in scientific mode. When you get to the TAN-1, hit the Inv key and you'll see TAN-1 show up.

If you're using Excel, you need to throw the DEGREES operator in front of the equation.

Rear Toe

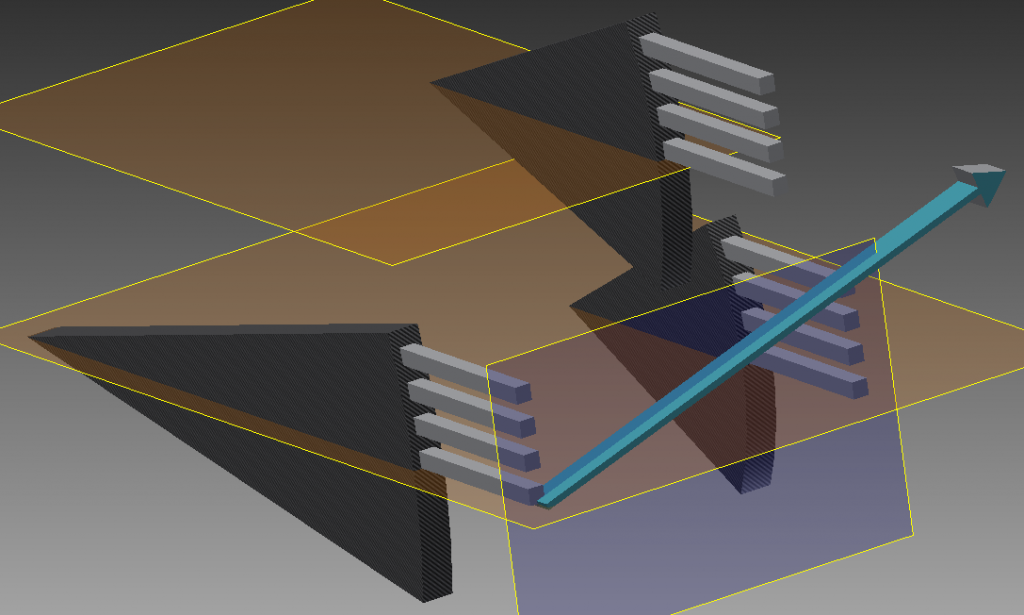

With the Control Blade suspension in the Focus, rear Toe and Camber are intertwined. As the suspension compresses or extends both will change. The best way I can show this is by picture:

![Image]()

I took the mounting points on the Rear Subframe and the lengths of the arms, found a range of 8 inches of total suspension movement (represented by the pies), placed them in a 3D space equal to the subframe mounting points. Then I drew a flat plane and measured to the arms. This gives me how far from a static plane the arms move, or in other words, the Camber and Toe imparted on the wheel. But do keep in mind that 8 inches movement at the arms is not 8 inches movement of the wheel, the wheel would be more movement; triangles again.

The arrow represents the direction of Toe/Camber. It's easiest to think of the Upper Control Arm as the main arm. The Lower Control Arm and Toe Link pull and push around the UCA. It's a bit tough to visualize and I don't know how to animate drawings, not for lack of trying.

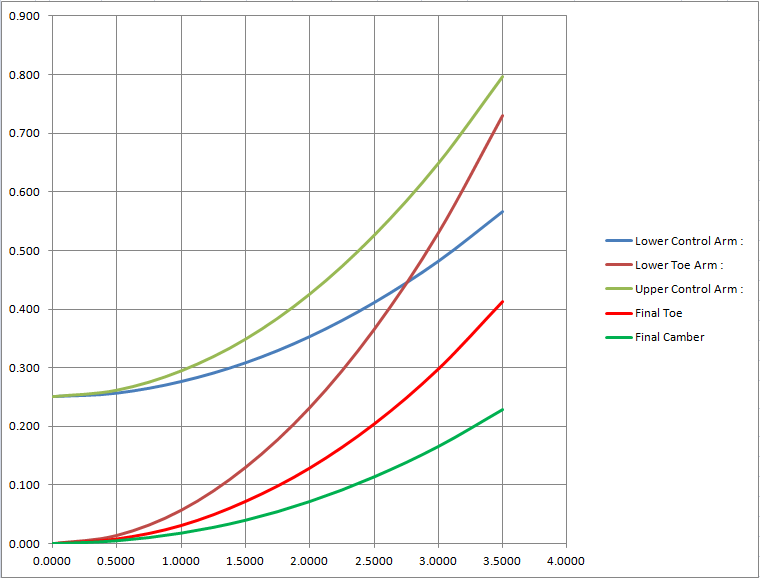

Here is the graph of those curves, in inches:

![Image]()

The math based on locations and lengths is a bit more complicated and I'm still working on it, working it into a spreadsheet. Once done I'll update again.

.... Stay Tuned ....

Files (click the title)

Ford Focus Camber & Toe - The file is Excel. Download it and you can adjust the arm lengths. Everything else is locked/password protected.

It's there to confuse you and not work like you think it should. Things like, why when I lower my car can I feel bumps more? and why does my back now have shooting pain?

Well, it may be in part to your not choosing parts correctly or fully understanding what you just got yourself into. So lets cover the basics so you do understand.

Starting with the fundamentals.

Modern automotive suspension is at it's most basic, a lever. We all know how a lever works, but we don't quite understand it fully or the types of levers. A wrench is a lever, and we all know that too long of a wrench and we either strip bolts or snap them off. So we have some understanding that a long lever delivers more Torque vs a short one. The question is, do we really understand why?

Back to Elementary School.

We've all played on the teeter-totter and we know that the fat kid would always get us stuck at the top ... if you were the fat kid, I hate you. No matter what we did, we could not get down or our weight to move him up.

This is because we were both the same distance from the Fulcrum. So his weight being more than ours, the Center of Mass is in his favor, and he pushes us up.

But what if we moved his weight closer to the Fulcrum? Would we stand a chance at moving him up and down?

Yes we would!

This is because the lever on his end is now shorter while yours is the same length. This moves the Center of Mass closer to the Fulcrum putting less Mechanical Advantage on the fat kid.

So if he weighed 130# and I was 65#, I would need twice the distance from the Fulcrum than he to balance the teeter-totter. Pretty simple concept to understand. The longer the bar, the more weight you can move or more work you can do.

But suspension is not a teeter-totter, there are not 2 bars extending from the Fulcrum. There is only 1. Is that still a lever?

Yes it is. It is a second order lever, like a wheelbarrow. You are still dealing with moving mass about a Fulcrum, except this time the ability to balance the bar depends on input work and the Center of Mass.

Lets say we have something heavy in our wheelbarrow, 100# of dirt. How much effort (work) do we have to do to lift that dirt?

Well that is going to depend on where the Center of Mass is and how long the handles are. So we need to define those things. We'll say the Center of Mass is 12 inches from the Fulcrum and our handles are 48 inches long

Now the question we want an answer to is, how much weight will it feel like we're lifting?

This is found by, dividing the location of the Center of Mass by the length of the bar, times the weight.

So, (12/48)*100# = 25#

And you can also see that if the weight moves further from the Fulcrum it feels heavier, and closer it feels lighter.

Suspension follows this same concept. The longer the lever (control arm) the greater the Mechanical Advantage it has over the same weight; and with a fixed length lever, the closer to the Fulcrum the weight is, the greater the Mechanical Advantage the lever has.

So lets apply some of this to the Focus, starting with the rear suspension.

Our rear control arm is about 19.5 inches long.

The spring, which supports the weight, is about 13.5 inches from the Fulcrum.

If the car has a 65/35 weight distribution and total weight is 2,850#, that means a single rear corner weighs about (2,850#*0.35)/2 = 498.75#.

But what does it feel like to the spring?

Applying our formula, (13.5/19.5)*498.75# = 345.29#

So because of the Mechanical Advantage that levers have, we do not need a spring rated for the full weight of the corner to support it in a neutral state. The spring does not see the full weight because 30% of the weight is closer to the Fulcrum than the end of the lever (Control Arm), where it would see the full weight of the corner.

So what does this mean in the real world? Well you want your control arm to have a range of controllable motion in two directions, up and down. This has to be about a central point (Static Ride Height), which is where the Mechanical Advantage of the Control Arm is 1, equal to that of the spring.

When the rating of the spring becomes greater than the corner weight, there is no downward advantage of the Control Arm. What I mean by this is that for the spring to compress it takes more weight than is present on the corner. This means a rough/stiff ride. Any bump will have to be combined with vehicle weight to move the suspension. Which means small bumps will disrupt the occupants and the car will not remain 'flat' (parallel to the road surface).

In a typical and predominately road going car, you want a spring with a lower rating than the corner weight. This will allow both upward and downward movement of the control arm and provide a mildly smooth and undisruptive ride.

In a predominately racing situation involving corners, where occupant comfort is not important, a stiffer spring can be used. Cornering load or G Force will increase the effective corner weight and the spring will move in a upward direction.

Based on our assumed corner weights, a spring no heavier than the total rear weight times the Mechanical Advantage of the Control arm should be used, anything more is just excess that will never be used.

So this is a maximum spring rate of, (2,850#*0.35)*(13.5/16.5) = 816.14#

But this only applies to side to side movement. Once you add weight from acceleration or remove from braking, that maximum changes. But if you have a heavy spring up front and not much upward movement, the weight transfer is very little. So that 816# becomes a pretty fair number.

Simply put, when you see someone with a rear spring rate of higher than 800#/inch, the rear will not 'rotate' or compress unless you hit a very large bump. And than it will be very disruptive. The wheel will move up and down though.

So how do we know how heavy of spring to choose?

To answer this we need to know the Range of Motion of the Shock Absorber.

The factory 2000-2007 shock has a Range of Motion of about 8 inches. And if we want equal movement in upward and downward directions we want the shock centered in that range, 4 inches. This will mean that when cornering we will not ever lift a tire off the ground and reduce cornering stability.

So now we need to bring some Geometry into the mix. Since the Control Arm is a fixed length and we assume the tire stays 90 degrees to it, we can use right triangles to find a equilibrium for the Shock Absorber.

Now being we've already figured the corner weight it becomes easy to find how far the spring compresses and in turn how far the wheel moves.

This is simply, corner weight divided by spring rating times the distance of the spring from the Fulcrum.

So a stock Focus Rear Spring has a rating of about 117#/inch.

(2,850#*0.35)/2 = 498.75#

-(498.75# / 117#/inch) * (13.5/19.5) = -2.95 inches

This means that in stock form, under hard cornering the opposite tire to the direction of the corner can lift off the ground about an inch under full compression. Not a good situation.

But lets find out how hard we have to corner for this to happen. Enter triangles.

So at full tilt our tire has to compress 5 inches. But this doesn't mean the spring has to compress 5 inches. It is inboard of the wheel and only sees a fraction of the total movement. The nice thing about right triangles is that it's easy to find out how much.

If we know the length of A, C and D we can find the length of B.

B = D/C*A

So, 13.5/19.5*5 = 3.46 inches

Now multiply the spring movement by the spring rating,

3.46 inches * 117#/inch = 405#

Or if you want to speak in terms of G Force, 405#/498.8# = 0.81 G's

To keep all 4 wheel on the ground one of two things needs to happen. Either we much use a softer spring or a harder spring. The first option will mean the static ride height is centered in the Range of Motion of the Shock Absorber. The second option will reduce the compression of the spring, but the same relationship will remain to lifting a tire. Only now it will take more cornering load to do so.

Lets find out the optimal spring rate to keep all four on the ground.

This means our static height needs to compress the spring 4 inches, as we said above.

(498.8#/4 inches)*(13.5/19.5) = 86.33#/inch

But this means at full tilt the spring is maxed out at,

4 inches * 86.33#/inch = 345.3# or in terms of G Force, 345.3# / 498.8# = 0.69 G's

Pretty low by anyone's standards. Very comfortable ride, just not a feeling of stability. On hard corners you'd be on the bump stop fully and and deformity in the road surface would toss the car around. This is why the harder spring is the normal practice and you're left with lifting a tire.

Now how stiff of a spring is needed to not lift a tire? Well there is no good answer. You will always lift a tire and it's because no matter what spring what you choose, it will not be in the Center of Motion of the Shock Absorber. To do so requires moving the spring down, an adjustable spring perch.

Here is the spring stiffness curve:

You can see that the relationship is not linear. There are actually what I would call comfort ranges:

85#/inch - 115#/inch - Ride Comfort Range

116#/inch - 165#/inch - Street Performance Range

166#/inch - 345#/inch - Street/Track Range

346#/inch + - Track Use Only.

Sticking with the full range of motion of stock parts, this chart is the heaviest spring you would ever need (represented by the intersect of the yellow lines); remember this is for 4 inches of compression:

That yellow line represents full vehicle weight on one rear tire. There is basically no way you will ever see this. So in factory form, there is no reason you'll ever need a spring that heavy.

So what does that mean? I know I've seen guys who race talk about really high spring rates.

It means that suspension travel is reduced with them. And this is the case with any heavier than stock spring, Total travel will be less & range of motion reduced. So when someone talks about having a spring with a rating like 480#/inch, you know that they don't have as much travel as a stock Focus. That also means large bumps are going to upset the occupants more than stock, the car will roll more.

____________________________________________________________________

Instead of moving on to the front, I'm going to cover rear alignment. I didn't plan on this getting this long winded, so organization can't be that great (you should see the mess inside my head).

Rear Alignment

Now if you take nothing else away from this post, I beg you to remember this section. Burn it into your brain. Tell it to someone else. Anything that will ingrain it into your permanent memory. Which shouldn't be too difficult being it will fly in the face of everything you've been told previously.

When people ask for alignment recommendations or give them, there is always information missing. Information that is very important, Range of Motion. If you don't know the RoM you can not give a justifiable recommendation. This is because the static alignment really means nothing. You suspension moves through a RoM and as it does, alignment changes. Thankfully this is predictable. The goal is to keep all the wheels flat to the ground so the tire has the maximum contact patch and the maximum grip. So as one side gains Camber the other should loose Camber, keeping the tires parallel to the ground.

As the Control Arm moves through it's RoM it follows an arced path, just the same as using a string tied around a pencil to draw a circle. A fixed length rotating around a center point, makes a circle.

That being the case, the tire is only flat to the ground when the control arms are parallel. To find this point you need to line all the bolts heads up. With all of them parallel, you can set Camber to zero, and only zero.

Now when the car turns, as one side drops and inch, the other raises and inch, positive Camber will equal negative Camber.

It does not matter what ride height you have or what suspension. The only thing that matters is where the zero point of Camber is and that it's predictable.

If done my way this will be your Camber Curve:

Now lets say you're lowered and the control arms aren't parallel, the wheel is located up from the Camber Adjustment Bolts and this is where you set Camber to zero.

Blue line is the path the Control Arm follows, it is absolute. The green line is what the tire now follows.

So now instead of the tire being negative Camber until after the Control Arm passes parallel, it is going possessive. You may think it'll change at the same rate, but it doesn't. Instead of being 4.11°; you are actually at 6.36°.

It takes less suspension movement to change Camber, or Camber changes faster.

On the compression side, you'd expect 4.11° negative camber; you actually get 5.39° of negative. Which is not equal to the 6.36° of the extension side. This is removing contact patch from the road surface and can cause the rear to act 'odd'.

It is this rate of change that must be equal to keep all four on the ground equally to ensure predictable steering at all times.

So if you are lowered, check you camber by measuring how far the outboard Control Arm Bolt is above the centerline and look at the picture. If you're 1 inch above, you should have -2.05° static Camber.

*Going back over my drawings, it seems the control arm lengths weren't correct (19.5 inches long) so the drawings are not accurate.

The chart below is based on the 19.5 inch Control Arm:

It should also be noted that the distance measurement is movement of the outboard Control Arm Bolt (centerline) relative to all the bolts being parallel. If you measure based on wheel movement, they will not work. Moving the wheel 1 inch is not moving the bolt 1 inch, go back to the triangle section if this doesn't make sense.

Rule: Always set rear alignment when the four control arm bolts are parallel.

We also want an equation based on Control Arm length. My 19.5 inch length probably isn't exact and I don't know if the newer Foci have longer or shorter. But we want a way to adapt to anything.

To find the Camber angle you only need to know 2 things, Control Arm length and the distance from the arms being parallel. Then you can input those into my equation and it'll spit out the angle.

TAN-1 ((SQRT (Control Arm Length^2 + Distance from parallel^2) - Control Arm length) / Distance from parallel))

(the equation doesn't format correctly because I can't get superscript to work

If you are using Windows Calculator, you want to be in scientific mode. When you get to the TAN-1, hit the Inv key and you'll see TAN-1 show up.

If you're using Excel, you need to throw the DEGREES operator in front of the equation.

Rear Toe

With the Control Blade suspension in the Focus, rear Toe and Camber are intertwined. As the suspension compresses or extends both will change. The best way I can show this is by picture:

I took the mounting points on the Rear Subframe and the lengths of the arms, found a range of 8 inches of total suspension movement (represented by the pies), placed them in a 3D space equal to the subframe mounting points. Then I drew a flat plane and measured to the arms. This gives me how far from a static plane the arms move, or in other words, the Camber and Toe imparted on the wheel. But do keep in mind that 8 inches movement at the arms is not 8 inches movement of the wheel, the wheel would be more movement; triangles again.

The arrow represents the direction of Toe/Camber. It's easiest to think of the Upper Control Arm as the main arm. The Lower Control Arm and Toe Link pull and push around the UCA. It's a bit tough to visualize and I don't know how to animate drawings, not for lack of trying.

Here is the graph of those curves, in inches:

The math based on locations and lengths is a bit more complicated and I'm still working on it, working it into a spreadsheet. Once done I'll update again.

.... Stay Tuned ....

Files (click the title)

Ford Focus Camber & Toe - The file is Excel. Download it and you can adjust the arm lengths. Everything else is locked/password protected.